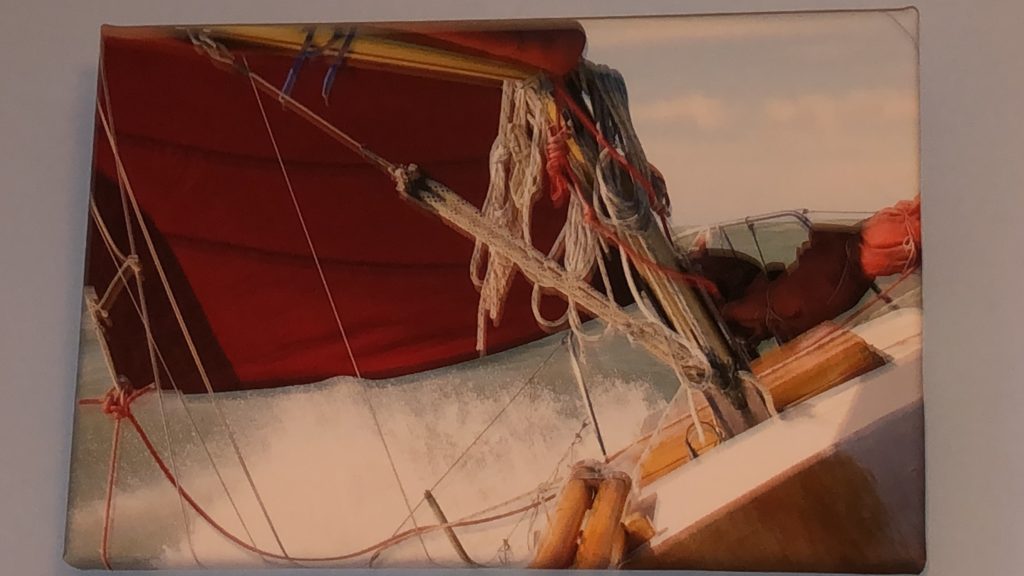

A reminder of better days to come…

After I had my sail on New Year’s Day, equally enjoyed by the mate and ‘boy’ it became increasingly likely that England would go into a full lockdown.

We did!

I got myself organised and collected various ‘pieces of wood’ from my little sailing tender Twitch and also the washboards and fore hatch from Whimbrel.

Some of this has been written about in an earlier post, see:

Many years ago, I made up a set of temporary wash boards and a fore hatch to allow these fittings to be brought home for maintenance.

The ‘bits of wood’ spent a few days in our conservatory drying out properly before even thinking about starting sanding and in the case of the hatch, a complete strip to bare wood.

Once the sanding was done, outside of course, I took over the conservatory breakfast table to apply the varnish coats. Clearly only one side at a time could be done – so for the wash boards a week and a half passed by before they were completed.

Interspersed with varnishing of wash boards and walking daily, the hatch was progressively stripped off with my new acquisition, a hot air gun stripper. The wonders of the internet when no shops are open. I’m converted almost entirely now!

The top of the hatch was stripped off with traditional liquid many years ago, probably around thirty…

I have said to my dear mate that the gun will come in useful when we do the cabin sides and sheer strake … her eye lids fluttered, not in normal expectation, but a kind of resigned horror. She said, ‘When…?’

‘That’s a good question,’ I said, adding, ‘probably the year before Whimbrel’s fortieth…’

Attacking the inside, which has had far fewer coats over the years was a bit more difficult. I had to be extremely careful with the gun as it had a tendency to singe the wood.

The power sander did the bulk of the middle areas but it was back to hand sanding for all the intricate corners and such.

Once all the sanding was done, it was a case of coat after coat.

On the inside I used ordinary gloss varnish (Blakes-Hampel Favourite) until the last few coats when I used a 50/50 mix of gloss and matt to give a sheen finish. I dislike the matt for it is far too ‘dead’…

That took a week! Then it was onto the top, overlapping onto sides.

The final coat to the top was taken round the bottom edge and sides too.

The hatch hinge screw holes have been re-drilled to suit new screws ordered on line, and is aboard Whimbrel awaiting fitting. I took opportunity to restock on a number of small sizes when ordering.

See: https://www.seaware.co.uk

What next?

Go sailing, I hope!